The Dewatering package of Kangan Petro Refining

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

1 General Overview and Process Description

2 Feed Specification

Below table shows the inlet sludge specification:

Kangan project Feed Specification | ||||

Stream | Flow(m3/hr) | TSS (ppm) | Density(kg/m3) | Flow(Ton/hr) |

Biological Sludge Stream | 5 | ~26000 | ~1050 | 5.2 |

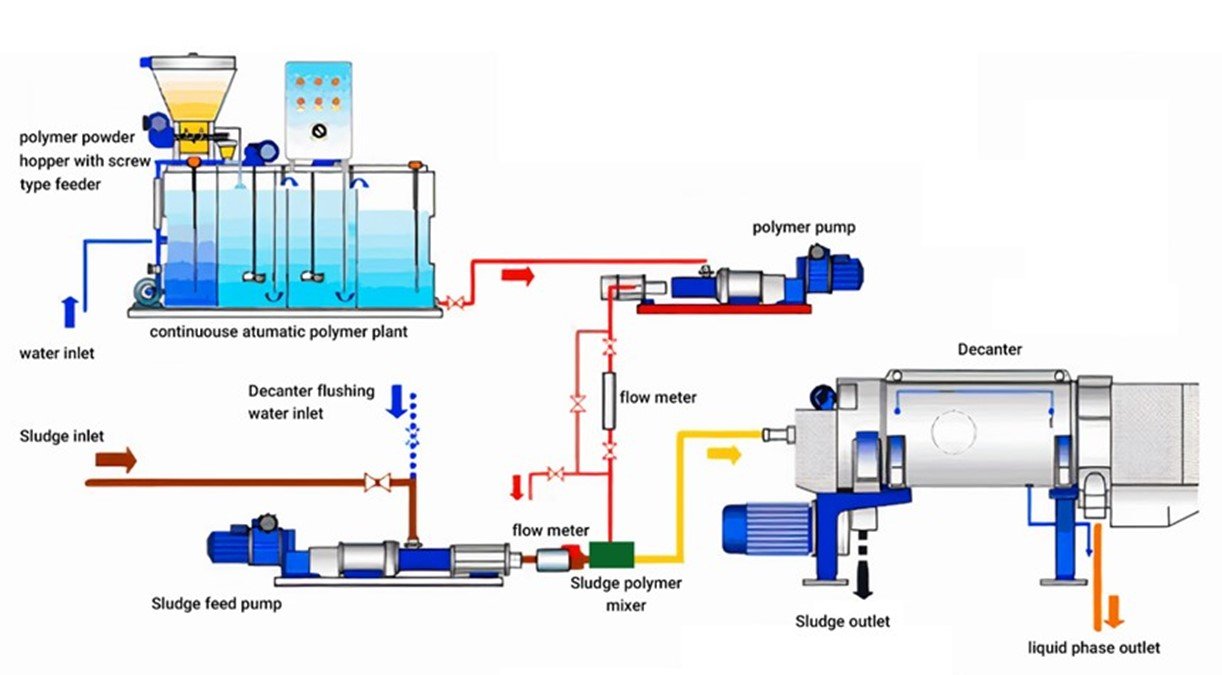

The addition of polymers is the most common method to increase the efficiency of Decanter for separating water and sludge. So, the Polyelectrolyte Dosing Package with three-compartment vessel and mixers designed for mixing dry Cationic Polyelectrolyte powder with water and homogenizing of solution.

The prepared polymer is mixed with sludge, which is pumped by sludge feed pumps. Then the conditioned sludge is transferred into a Centrifuge Dewatering Machine (Decanter). The sludge cake from the centrifuge contains at least 20% solids, and solids capture of a minimum of 95 percent is achieved.

3 Discharge Specification

Kangan project Products | ||

Stream | Flow(m3/hr) | Solid (ppm) |

Supernatant | ~5.6 | ~4000 |

Sludge Cake | ~0.3 | ~350000 |

Required Utility:

- Plant Water

- Electricity

4 Schematic of Kangan Dewatering Package is shown as below: