Projects

Projects

We always get the job done

Zirsakht Tadbir Arian (ZETA) Company is an innovative company with an interest in running state of art projects and using new methods and technologies. In our projects, we always improve performance and efficiency and bring it to the next level.

Quality is our obligation. With step-by-step quality control, we always make sure to deliver projects with the highest quality. We have specialized engineers who work together to complete a project, hence, we consider every aspect of each project.

Saving the environment is one of our most important values, using high-tech equipment along with novel engineering knowledge, has allowed us to run environment-friendly projects.

Featured projects

You can see some of our projects in the list below.

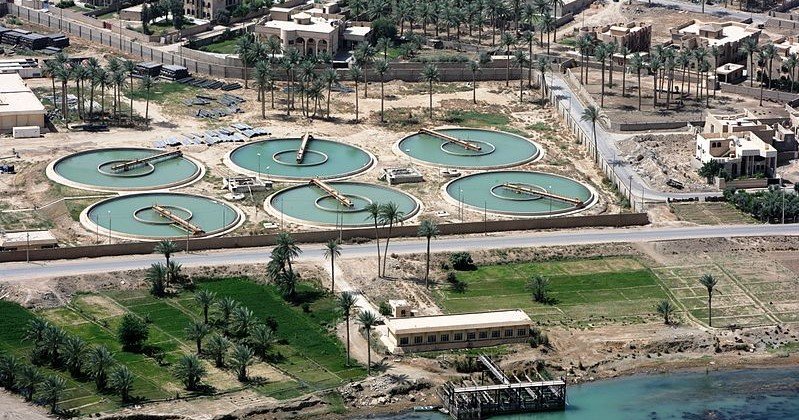

Karbala Wastewater Treatment Plant

Location: Iraq

Description : Physical and biological methods of municipal wastewater treatment with biogas treatment system and CHP power generation

ZLD+MLD For The Wastewater Treatment Of Isfahan Oil Refinery

Location: Iran , Isfahan

Description : Our task in this project was to purify the wastewater by combining MLD and ZLD technologies.

Kangan Petro Refinery Dewatering Package

Location: Iran , Kangan

Description : Engineering and designing of sludge dewatering package for Kangan petro refining

The Isfahan Oil Refinery UF package

Location: Iran , Isfahan

Description : Our task in this project is to purify the water by an ultrafiltration system to achieve ideal water parameters for RO feed.

The Esfahan Oil Refinery Demineralization (DM) Water Treatment Plant

Location: Iran , Isfahan

Description : Demineralization (DM) Water Treatment Plant for ISFAHAN OIL REFINERY UTILITY & OFF-SITE PROJECT FOR DHT to provide demineralized (DM) water.

ZLD Package For Ilam Petrochemical Complex (ILPC)

Location: Iran , Ilam

Description : Engineering, designing and procurement of ZLD plant for treating industrial wastewater.