Minimum Liquid Discharge

Minimum Liquid Discharge

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Quis ipsum suspendisse ultrices gravida. Risus commodo viverra maecenas accumsan lacus vel facilisis.

Browse Other Water and Wastewater Treatment Technologies

- Pre-Treatment

- Biological Treatment

- Sludge Treatment

- Minimum Liquid Discharge

- Zero Liquid Discharge

- Post-Treatment

- UV Systems

- Dosing Packages

Our Services

Download (.PDF,250KB)

Catalog 2021

Download (.PDF,250KB)

Product presentation

Watch

Latest promo video

Minimum Liquid Discharge Treatment

Minimum Liquid Discharge (MLD) is an approach aimed at reducing waste discharge from diverse industrial wastewater treatment facilities. This process involves recycling wastewater within the system to minimize environmental discharge. MLD systems, characterized by their complexity, demand meticulous design and monitoring for optimal effectiveness. Typically, they complement other water treatment methods to enhance environmental conservation and resource recovery, targeting a wastewater coverage of over 70%.

About the MLD Process

The MLD (Minimum Liquid Discharge) process encompasses various methods. Zirsakht Tadbir Arian Company primarily utilizes the Reverse Osmosis (RO) method as the core MLD technique, which can be complemented with pre-treatment and post-treatment methods tailored to the specific characteristics of the incoming wastewater.

We specialize in the design and implementation of cutting-edge MLD and RO systems that yield exceptional water recovery rates within MLD systems. Our RO systems encompass both conventional RO and Batch RO technologies.

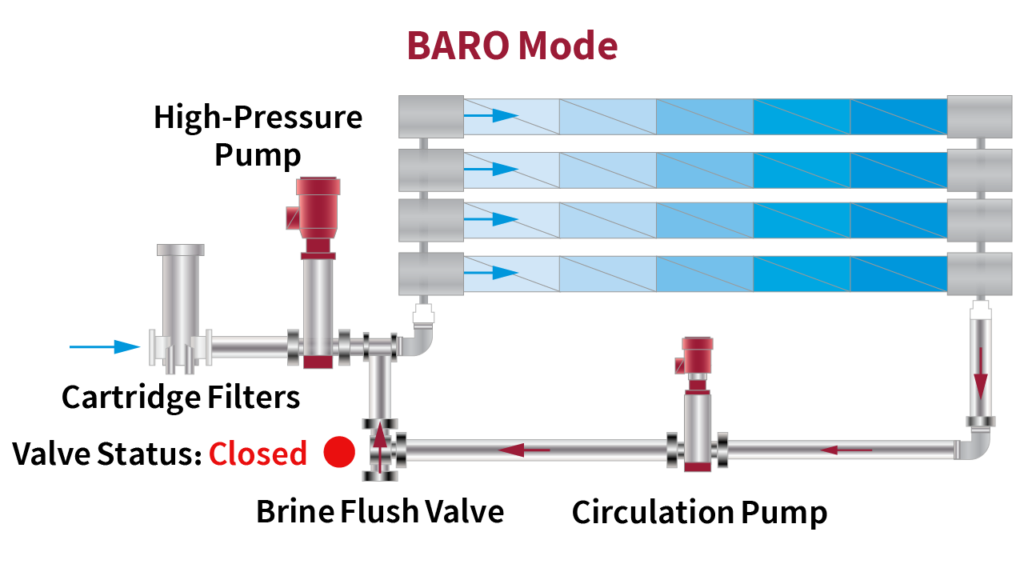

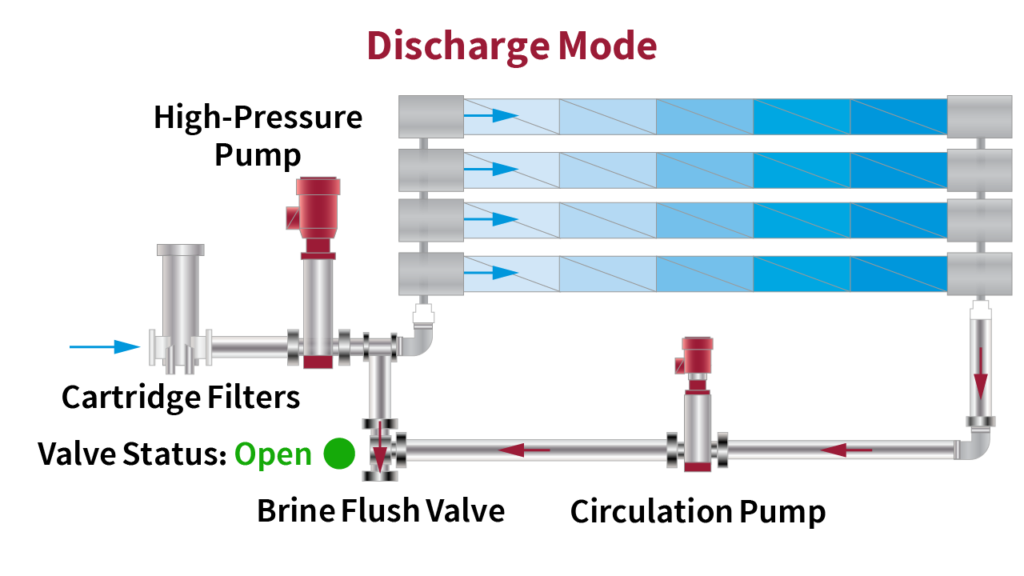

Batch RO (BARO)

BARO (Batch RO) is a new type of closed-loop reverse osmosis system that operates semi-batch, taking advantage of dead-end filtration. In this batch RO process, the feed is continuous, while the reject stream or concentrate is recirculated internally to provide turbulent flow and prevent salt precipitation.

The BARO concentrate is recirculated to the feed until one of the three objectives is met:

Conductivity reaches a preset set point.

The maximum working pressure, as defined above, is reached.

The expected conversion is obtained.

and then purged from the system by entrainment with the influent water itself.

Features and Advantages of BARO:

Maximum Recovery (at least 15%-30% more than conventional RO)

Less Brine Waste

Greater Reliability through reduced fouling and Scaling

Unmatched Flexibility

Less Energy

to precipitate out metals, the materials that may cause hardness, and silica.

to help facilitate the precipitation, flocculation, or coagulation of any metals and suspended solids

to concentrate secondary solid waste after pretreatment or alongside an evaporator

To remove all the leftover trace amounts of suspended solids and prevent fouling, scaling, and/or corrosion

To remove the bulk of dissolved solids from the water

To further concentrate the reject RO stream or further reduce waste volume

For vaporizing water and other remaining liquids before crystallizer.

To boil off any remaining liquid and produce a dry, solid cake ready for disposal

Single Service

Downloads

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit.

- Download bochure (DOC)

- Download bochure (PDF)

- Rules about service apply generally

- Users manual