ZLD Package For Ilam Petrochemical Complex (ILPC)

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

1 The Facility

The Ilam Petrochemical Complex (ILPC) consists of the following plants:

- Olefin plant (450,000 ton/y)

- HDPE plant (300,000 ton/y)

- Power (100 Mwh) & steam generation plants (120 ton/h)

- Utility units and offsite

2 Feed Specification

Ilam ZLD feed water is a mixture of 4 streams:

Stream #1: DM and Polishing Unit Waste (Regeneration)

Stream #2: RO Reject

Stream #3: High TDS Stream (The main source of this stream is from the treatment of Spent Caustic which already passed the WAO package)

Stream #4: SRU Wastewater (This stream is a mixture of 2 other streams named Spent Water and neutralized Caustic)

Specification of the total mixture is as below table:

Ilam ZLD Feed Specification | ||||

Stream | Flow(m3/hr) | % Solid(w/w) | Density | Flow(Ton/hr) |

Total | 33.5 | 4.37 | 1.06 | 35.36 |

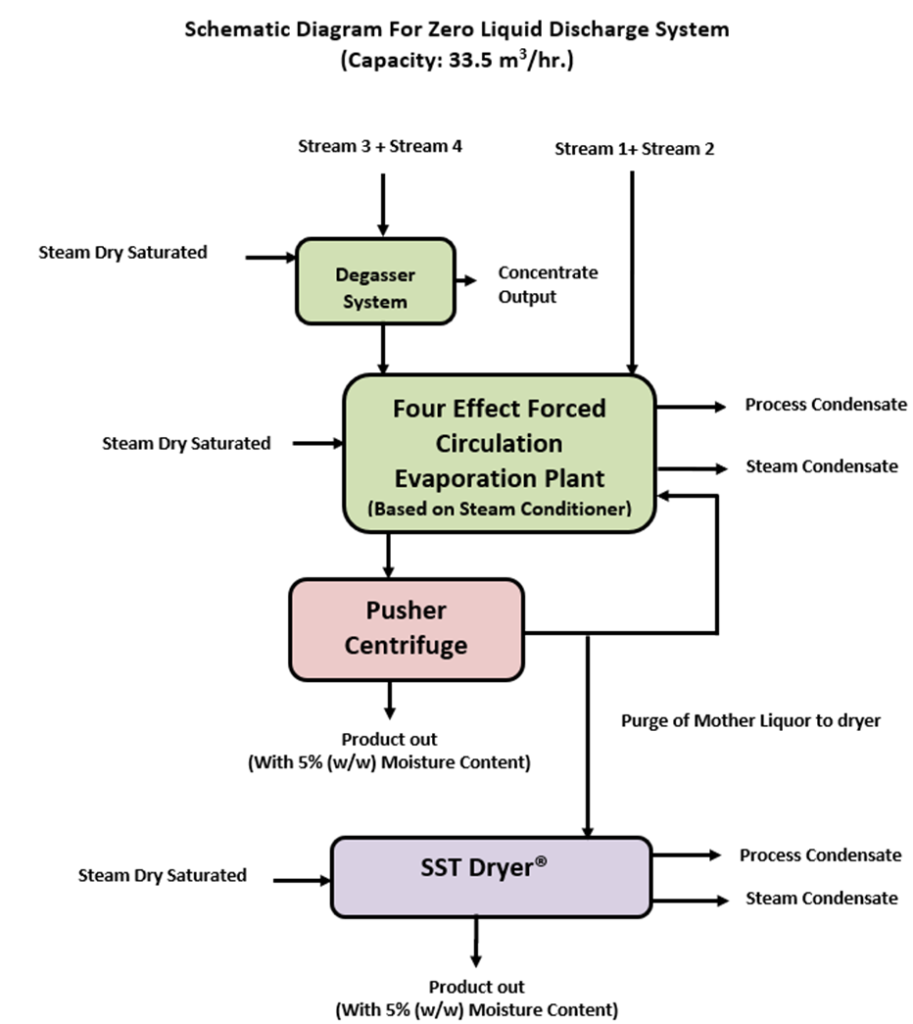

3 General overview and process description

Ilam ZLD consists of below main units:

Degasser system: As streams 3 and 4 of feed streams contain Sulfur content which causes H2S gas production, before entering these two streams to the MEE unit, they have to be degassed. So, a degasser unit was designed and installed. Products of this unit are condensate water and degassed wastewater. Finally, the degassed wastewater is discharged to the storage tank to be mixed with Streams 1 and 2.

The Multiple Effect Evaporator (MEE): The Multiple Effect Evaporators are vertical shell and tube heat exchangers with a recirculation pump at the bottom. The calandria is connected to a vapor-liquid separator. The recirculation pump pumps the effluent through the tubes of the calandria, and into the vapor-liquid separator. The water gets separated from the effluent due to flash evaporation in the vapor-liquid separator. Products of this unit are condensated water and slurry wastewater.

- Client : Tyler Inc.

- Location : California City FL 23059

- Area : 1.690 m2

- Finished On : September 17, 2014

- Value : $789.000,00

- Remarks : The project was completed under the budget, with the savings returned to the owner.

Pusher Centrifuge & Dryer System:

By the time the concentrated wastewater reaches the last evaporator stage, the concentration of the salts increases beyond their solubility limit. This concentrated wastewater is named Slurry. Now it is needed to separate salts from Slurry. Due to this aim Pusher centrifuge and SST dryer systems are used. The products of this unit are salt and condensate water.

4 Discharge Specification

Ilam ZLD Products | ||

Stream | Flow (kg/h) | Specification |

Crystal clear water | ~33500 | TDS< 100 |

Salt | 1633 | Mositure< 5% |

5 Required Utility

- Cooling water

- Steam

- Electricity

- Instrument air

Schematic of process is shown below:

Image depicting the feed water of the Ilam Petrochemical Complex ZLD system (TK-10) alongside the outlet water (P-013).

Solid salt output from the Zero Liquid Discharge (ZLD) system.