Gachsaran Olefin Project

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

1 General Overview and Process Description

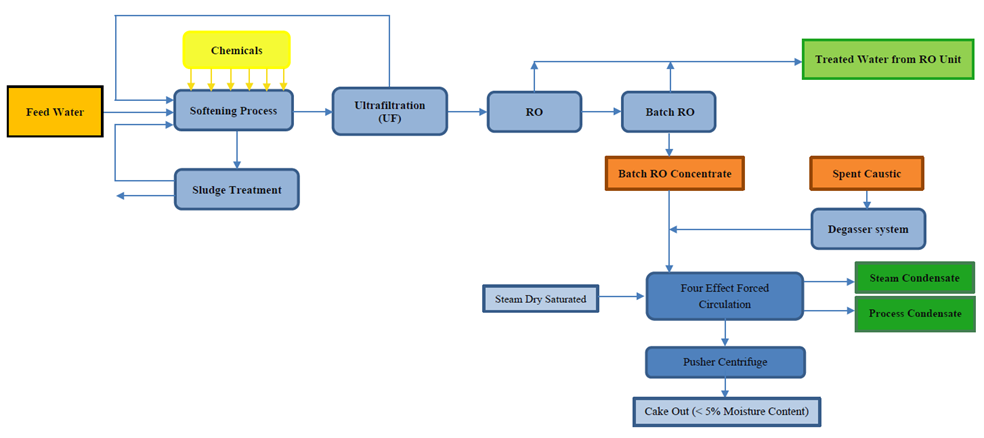

This part describes the process of the CSW+ZLD plant, based on a softening, an ultrafiltration, two Units of reverse osmosis (RO1+ Batch High Pressure RO), and a multiple effect evaporator.

Our treatment process for GACHSARAN OLEFIN PLANT is planned to receive RO brine from the water treatment plant with an average capacity of 6000 m3/d and this flow rate can be increased to 8400 m3/d.

The softening step consists of the following main equipment:

- CSW Storage tank

- Softening reactor

- DAF separators

- Sludge storage tank-thickener

- Press filter

After the softening step, water passes through a self-cleaning filter (100 microns) then Filtered water comes to UF trains. Each train has 36 modules of dead-end membranes. The effluent of UF is the feed of advanced treatment:

- UF

- RO

- Batch High-Pressure RO

- ZLD

2 CSW Plant

Feed Specification:

Gachsaran CSW Feed Specification | ||||

Stream | Flow(m3/hr) | TDS (ppm) | Density(kg/m3) | Flow(Ton/hr) |

RO Brine from WTP | 250 | ~8700 | ~1000 | 250 |

CSW consists of below main units:

Prefiltration; Softening reactor, HPD (High-Performance Decanter) with Lammella, Self-cleaning filter. Softening units has been considered to reduce iones which increase scaling in RO units or cause the need for larger RO units. To reach these aims an innovative cold softening has been designed with lower chemical/ energy consumption.

Ultrafiltration process; UF physically separates solids from liquid streams based on the principle of size-exclusion.

Reverse osmosis process; Consists of multi-stage RO and Batch RO for the removal of dissolved inorganic solids from water. Batch RO systems will conserve water, and reduce brine waste and energy consumption.

CSW Discharge Specification:

Gachsaran CSW Products | ||

Stream | TDS (ppm) | Flow(Ton/hr) |

Permeate Water | <200 | 248 |

Batch RO Concentrate | ~140000 | ~16.0 |

3 ZLD Plant

Feed Specification:

Gachsaran ZLD Feed Specification | ||

Stream | % Solid(ppm) | Flow(Ton/hr) |

Batch RO Concentrate | ~140000 | ~16.0 |

Spent Caustic | – | ~6.7 |

ZLD consists of below main units:

Degasser system: As Spent Caustic contains Sulfur content which causes H2S gas production, before entering this stream to the MEE unit, they have to be degassed. So degasser unit was designed and installed. Products of this unit are condensate water and degassed wastewater. Finally, the degassed wastewater is discharged to storage tank to mixed with Batch RO Concentrate Stream.

The Multiple Effect Evaporator (MEE): The Multiple Effect Evaporators are vertical shell and tube heat exchangers with a recirculation pump at the bottom. The calandria is connected to a vapor liquid separator. The recirculation pump pumps the effluent through the tubes of the calandria, and into the vapor liquid separator. The water gets separated from the effluent due to flash evaporation in the vapor liquid separator. Products of this unit are condensate water and slury wastewater.

Pusher Centrifuge & Dryer System: By the time the concentrated wastewater reaches the last evaporator stage, the concentration of the salts increases beyond their solubility limit. This concentrated wastewater is named Slurry. Now it is needed to separate salts from Slurry. Due to this aim Pusher centrifuge and SST dryer systems are used. Products of this unit are salt and condensate water.

ZLD Discharge Specification:

Gachsaran ZLD Products | ||

Stream | Flow (kg/h) | Specification |

Crystal clear water | ~20100 | TDS< 100 ppm |

Salt | ~2600 | Mositure< 5% |

Required Utility:

- Cooling water

- Low-Pressure Steam

- Electricity

- Instrument air

4 Schematic Block Diagram of CSW+ ZLD process is shown as below: