The Isfahan Oil Refinery UF package

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

1 The Facility

Isfahan Oil Refinery has been operating in the field of crude oil refining and petroleum products production and downstream feedstuffs since 1979 and now produces about 23% of the country’s petroleum products.

The company is located in the northwest of Isfahan with a total area of 340 hectares.

2 General Overview and Process Description

This part describes the process of the Ultra Filtration (UF) package for the Isfahan Oil Refinery Utility & Off-Site Project for DHT.

This project including UF package Engineering and Assembling for treating the waste water with an average capacity of 12000 m3/d in order to reuse the water as R.O. feed water.

Feed Specification

Influent feed water of UF Package is pretreated waste water which is taken from DAF (Dissolved Air Flotation) units as described in below table;

Isfahan UF Package Feed Specification | ||||

Stream | Flow (m3/hr) | TSS (ppm) | Density (kg/m3) | Flow (Ton/hr) |

Wastewater Stream | ~500 | ~15 | ~1000 | ~500 |

- The standard chunk of Ipsum used since the 1500s

- Cicero are also reproduced in their exact original form

- English versions from the 1914 translation by H. Rackham

- Literature from 45 BC, making it over 2000 years old

- This book is a treatise on the theory of ethics very popular

- Cicero are also reproduced in their exact original form

- Client : Tyler Inc.

- Location : California City FL 23059

- Area : 1.690 m2

- Finished On : September 17, 2014

- Value : $789.000,00

- Remarks : The project was completed under the budget, with the savings returned to the owner.

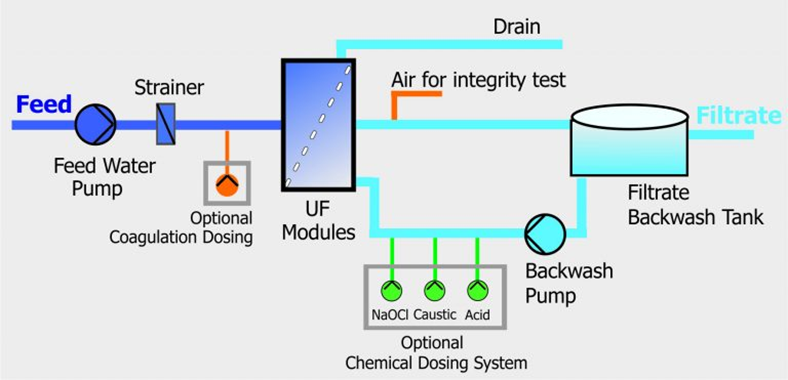

3 Ultrafiltration process

Ultrafiltration (UF) is part of the family of pressurized membrane filtration systems that physically separate solids from liquid streams. These systems are designed for fully automatic operation.

A control mechanism is used to control the various operating modes of the ultrafiltration process: filtration, cleaning, and backwashing. This project consists of 3 UF trains with all equipment and dosing packages. Each train of UF has 52 modules of dead-end membranes.

Discharge Specification:

Isfahan UF Package Discharge Specification | |||

Stream | TSS (ppm) | Density (kg/m3) | Flow (m3/hr) |

Filtered Water | ~Nil | ~1000 | ~500 |

Required Utility:

- Electricity

- Instrument air

4 Schematic of UF package is shown as below